- Products

- Solutions

- Service

- Company

The collaboration between the mechanical engineering companies Tox Pressotechnik and MiniTec has paid off: a customer from the electrical industry can clinch galvanized sheets reliably thanks to the use of a powerful machine tong including press module from Tox in combination with a special XY table from MiniTec. A big plus: the operator does not have to change any tools.

To join galvanized sheet metal, we recommend clinching," explains Marco Unger, sales representative at Tox Pressotechnik in Weingarten, Swabia. "The zinc layer can flow along with the joining process, there is no need for post-galvanizing as with spot welding, and there is no corrosion," he explains.

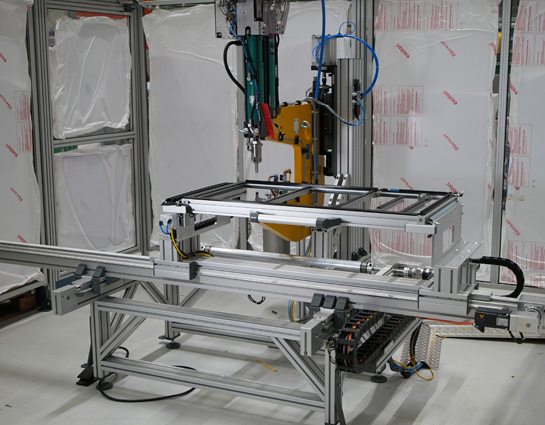

An end customer wanted to optimize its processes and specified the processing sequences precisely: The worker places the component on an XY table, moves away from the monitored danger zone and presses the start button. The PLC now runs the joining program. The table is first brought into the desired position. The free-moving carriage then moves the grippers upwards so that the die fits snugly under the sheet. The punch of the Tox machine tongs is aligned from above and joins the sheets.

The tongs are then moved downwards and the table is aligned for the next joining point.

The TZ machine tongs (yellow) and a 50 kN press module (green) from Tox Pressotechnik.

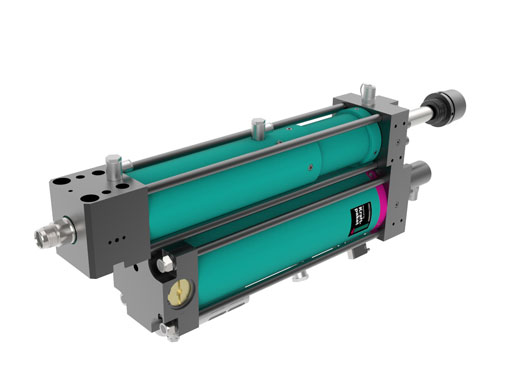

The TOX power pack type RZK equipped with the proven power bypass and hydraulic end position damping is used.

Solution from a single source

"Here, two experts in their respective fields have developed a complete solution from a single source," says Frank Stattaus, customer consultant at MiniTec in Schönenberg-Kübelberg, Rhineland-Palatinate, describing the collaboration. Tox supplied a TZ 05 machine tong with compensating slide and internal control for clinching.The Tox power pack RZK is used as the drive.

MiniTec acted as general contractor for this project and developed an XY table with a flexible base frame. A safety fence with light curtain ensures safety. A higher-level control system regulates the approach of the various components and joining points. The combined solution has paid off for the end customer. The sheets can be clinched reliably and permanently without causing corrosion problems later on. The system currently joins 14 components of different sizes with a varying number of clinching points.

The end customer has also become more flexible: The system can be quickly and easily programmed for new components.

Do you need a suitable solution or an approach for your project? Then please contact us!