- Products

- Solutions

- Service

- Company

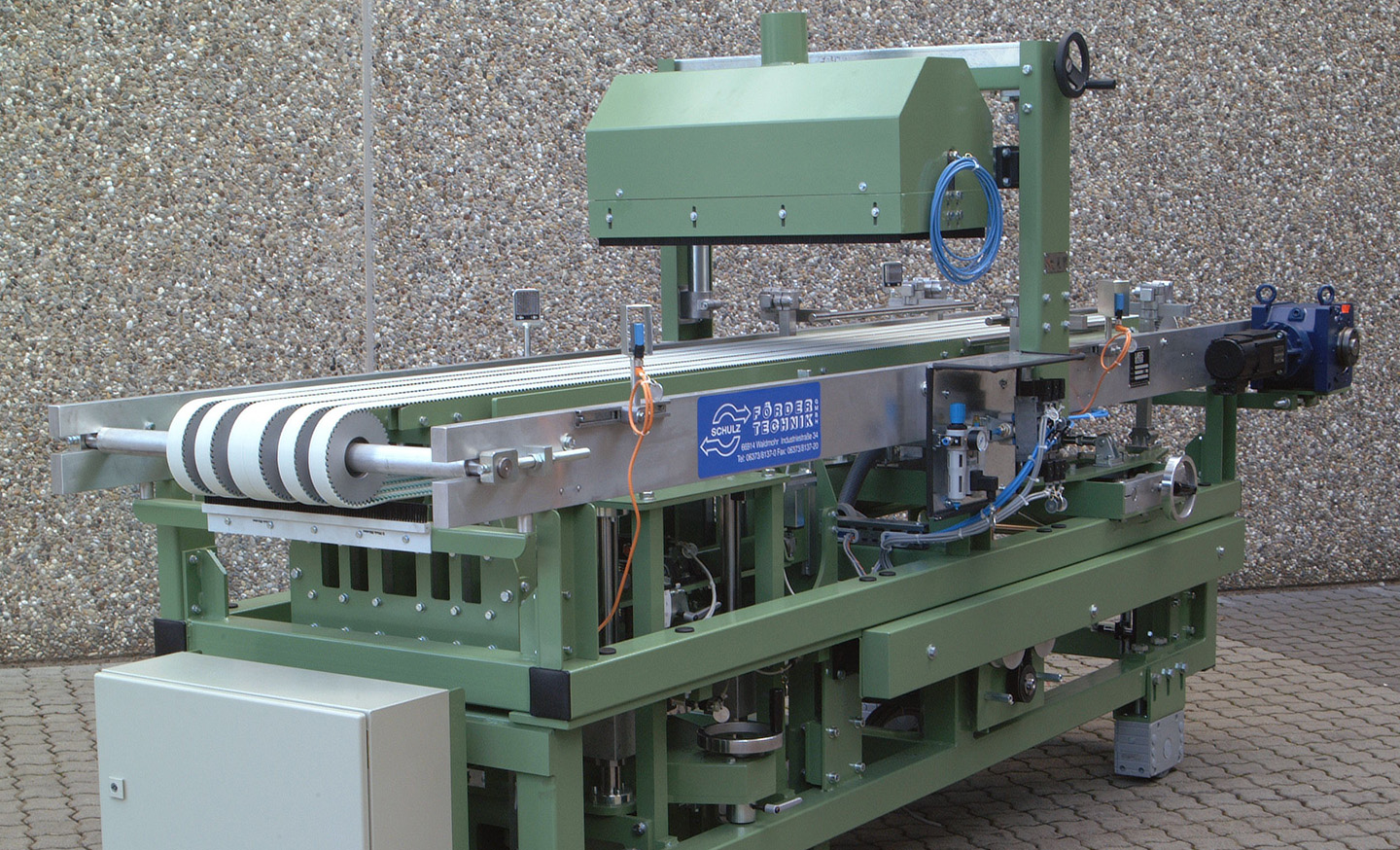

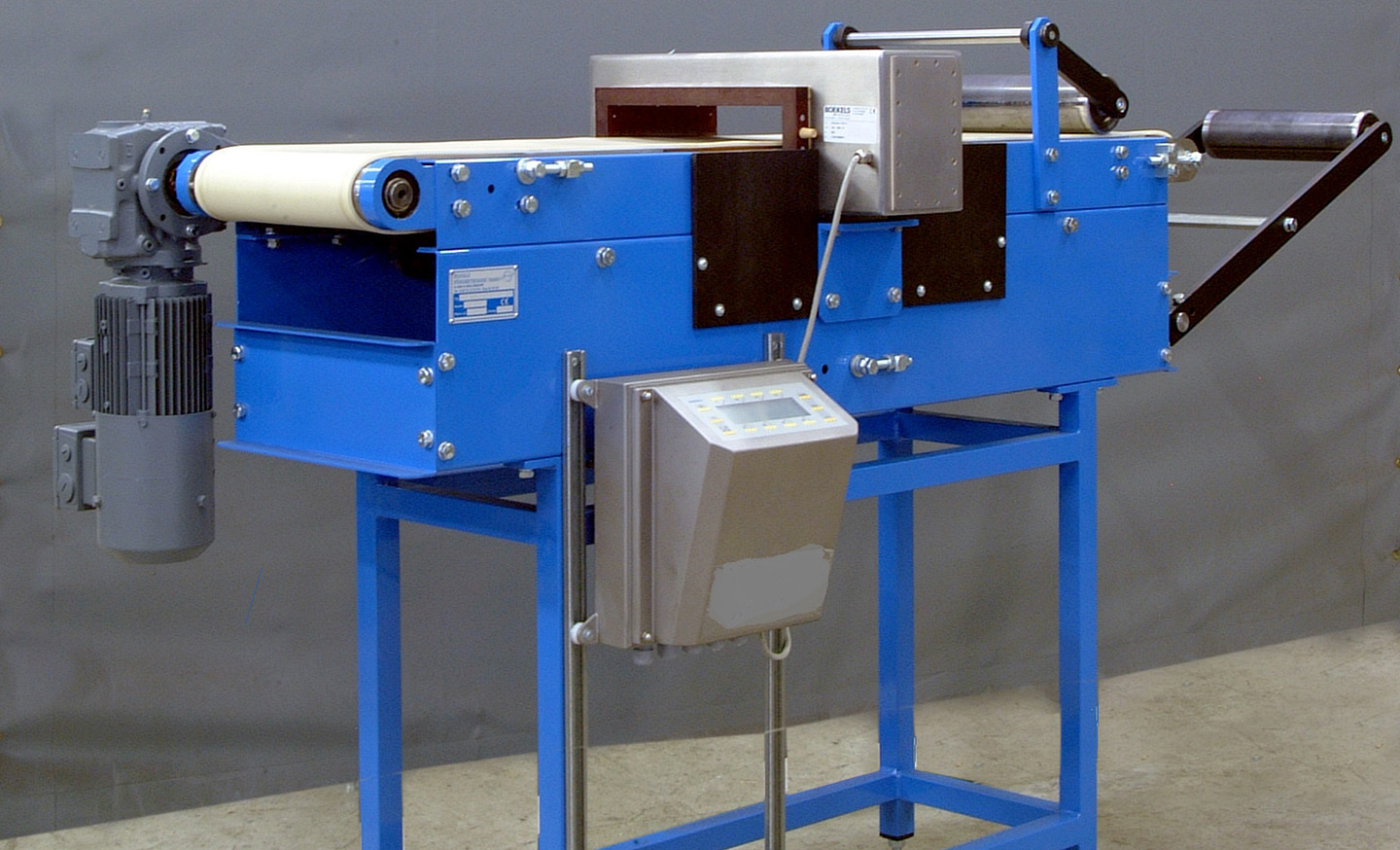

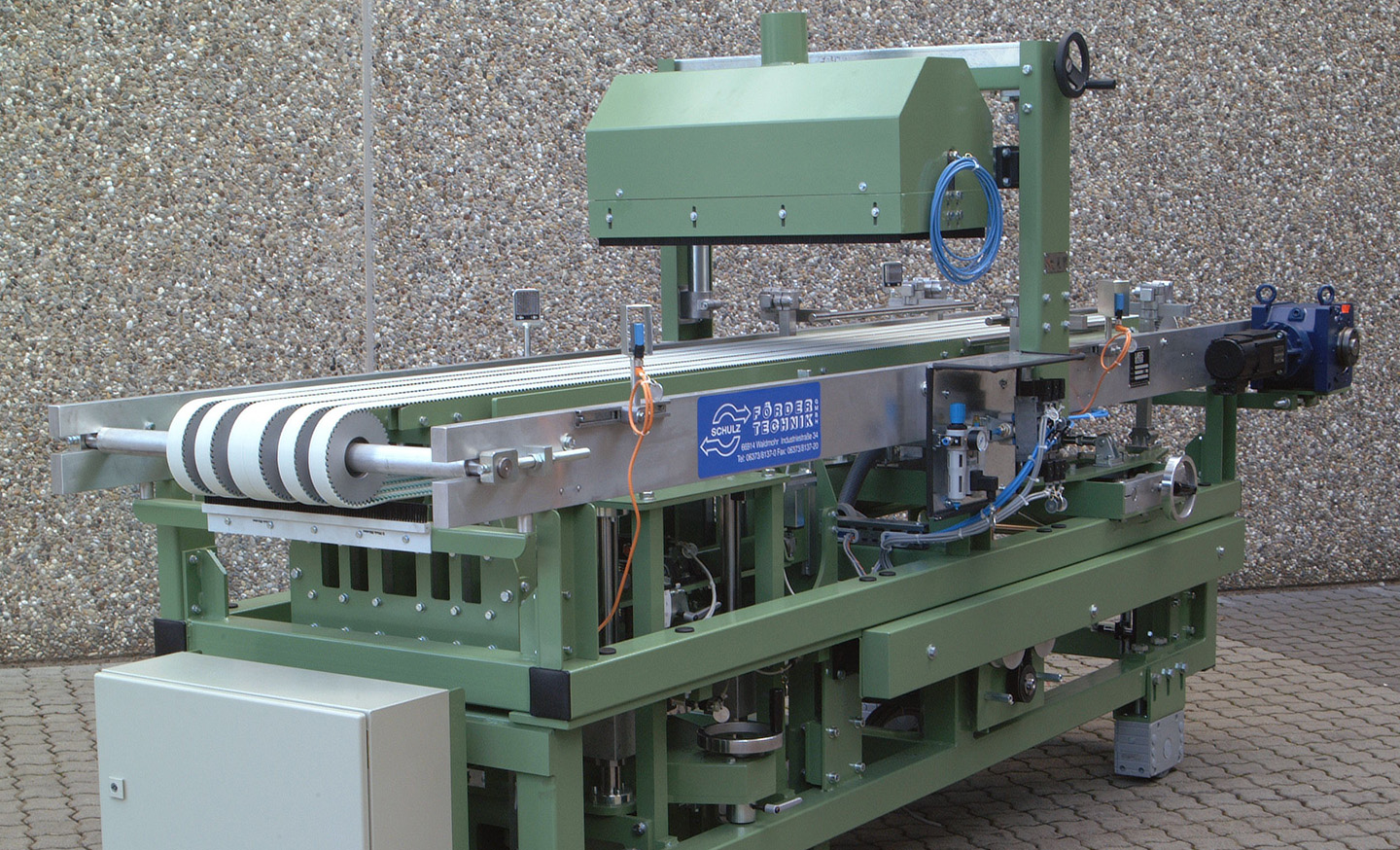

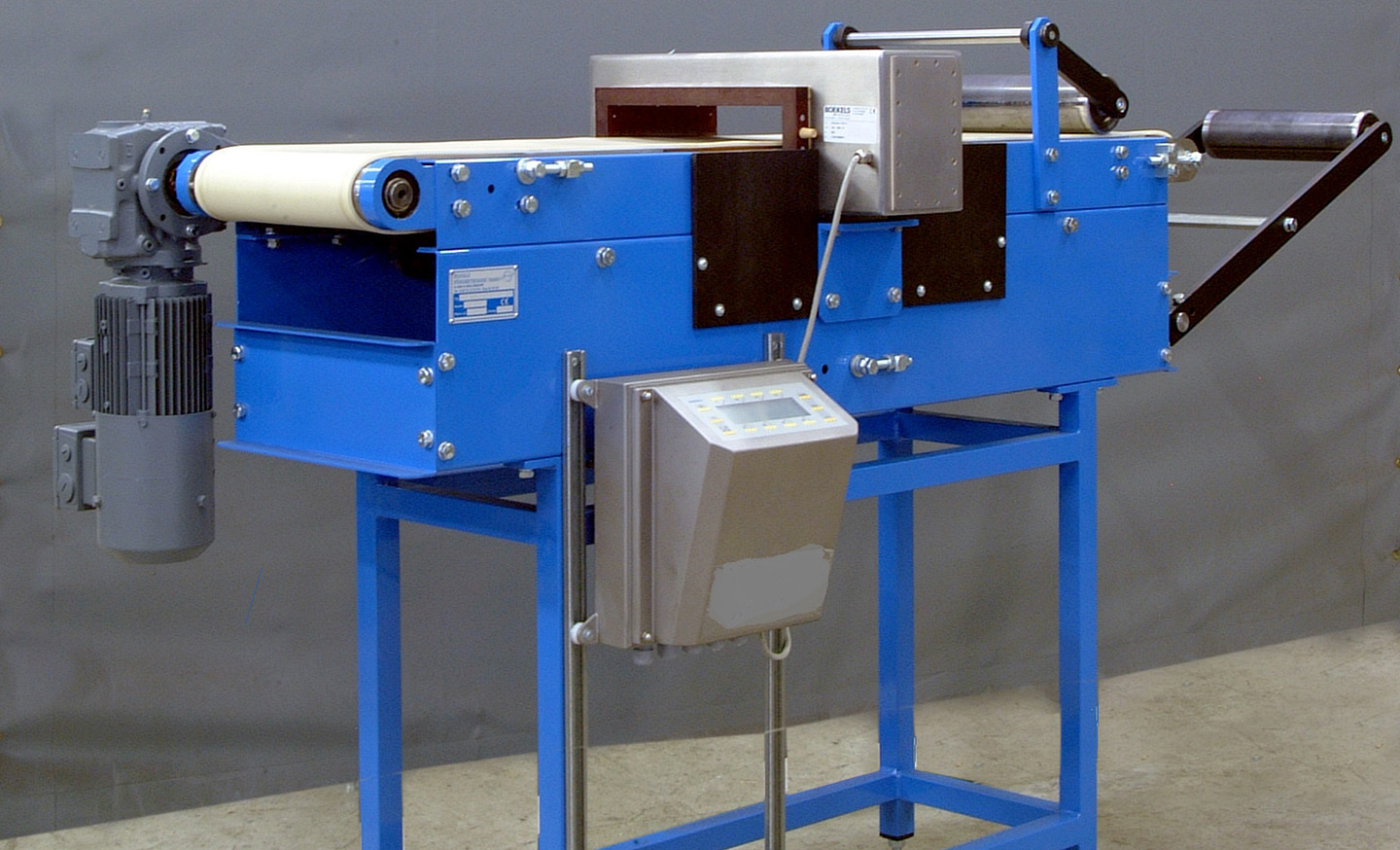

MiniTec conveyor systems made of steel and stainless steel are always used when greater load-bearing capacity or special hygiene requirements are needed. But also when acids and other chemicals come into play or temperatures reach extreme ranges.

Such requirements are particularly common in the food, pharmaceutical and chemical industries. In food production, for example, there are high hygiene requirements for surfaces and the simplest possible cleaning of systems. The situation is similar in the manufacture of chemical or pharmaceutical products. Here, steel or stainless steel are the best solution.

Since the takeover of Schulz Fördertechnik GmbH by MiniTec, a highly experienced team has been on hand to meet these special challenges. The company has been supplying steel and stainless steel conveyor systems to customers in the food and pharmaceutical sectors for many years and has built up a good reputation in these areas. Together with MiniTec's expertise in the field of conveyor technology and automation, complete conveyor systems are created according to individual customer specifications.

Thanks to the high-quality components used, the solutions are characterized by low susceptibility to faults and low maintenance requirements. They include not only the conveyor lines, but also the drives and automation. The customer receives complete systems that are designed, assembled, installed and supported with maintenance and services right up to the start of production and beyond.

Do you have any questions or would you like to find out more about our Conveyors made of steel and stainless steel ?

Thanks to the high-quality components used, MiniTec conveyor systems are characterized by low susceptibility to failure and low maintenance requirements.

The customer receives complete systems that are designed, assembled, installed and supported with maintenance and service until the start of production and thereafter.