- Products

- Solutions

- Service

- Company

The AOP tester is an optical measuring device built by ISW GmbH in cooperation with MiniTec. It works fully automatically, measures and evaluates twelve product parameters without contact within one minute. IO products are fed back into production, NIO products are rejected and ejected. Of course, the technology can also be adapted to other requirements.

In addition to high precision, some measuring tasks also require non-contact measurement (pharmaceutical, medical, food technology), for example if contamination would occur through human hands. The task is very challenging when many parameters have to be measured in a short time and in a very confined space. ISW GmbH has successfully solved these challenges with the development of the AOP tester (Automatic Optical Product Tester). The version shown here can measure up to twelve parameters on a workpiece, in some cases simultaneously. And it does so on a very small footprint.

Use of small robots

This is made possible by the use of a high-precision small robot that picks up the parts and feeds them to the various integrated measuring stations. Once the series of measurements has been completed, the evaluation software decides whether the part is returned to the production cycle as "IO" or rejected as "NOK". The solution is based on self-developed evaluation and control algorithms that can be adapted to individual circumstances. The solution currently on show has increased the throughput of measurements by a factor of 60 and is capable of working around the clock. In addition, all "IO" tested parts can be reused, whereas in the past, contact with people meant that the test parts had to be disposed of.

The AOP-Tester.

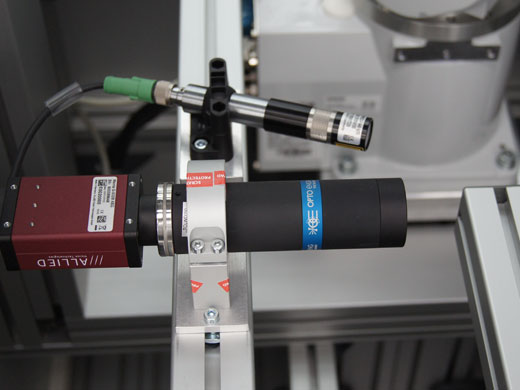

Measuring device of the measurement station.

Many areas of application

This development results in many alternative areas of application in a wide range of industries where high precision, non-contact measurement and speed are required. The advantages of the system include high-precision positioning (+/- 30 μm reproducible), high-precision measurements (+/- 100 μm, better if necessary), contamination-free measurements and an adjustable individual test sequence. A large number of measurements can be combined with a high throughput and low maintenance requirements.

Do you need a suitable solution or an approach for your project? Then please contact us!