- Products

- Solutions

- Service

- Company

How robotics and intelligent automation are changing the future? And pave the way for a sustainable economy? You will find the answers at automatica 2025 - with the major focus topics: ‘Digitalisation and AI’, ‘Sustainable production’ and ‘The future of work’. In addition to concrete practical applications and exciting product innovations, the exchange with key players and industry experts is a top priority. Join us and secure your knowledge advantage. Because challenges need solutions.

At MiniTec, the trade fair is all about:

Venue: Trade Fair Centre Messe München

Event date: 24. - 27. Juni 2025

Opening hours: 09:00 - 17:00 Uhr (on the last day until 16:00 Uhr)

MiniTec is located in hall A5 at booth 32

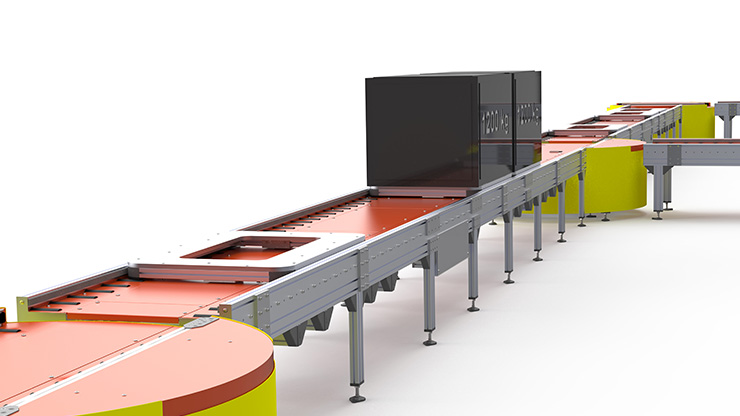

RMS Max is a further development of the RMS roller assembly system and can transport workpieces three times as heavy as the latter, namely up to a weight of 1000 kg per linear meter.

The solution, also known as a workpiece carrier transfer system, is based on heavy-duty accumulation rollers that allow free circulation for assembly, testing and processing tasks. The workpiece carriers can be accumulated and buffered, and manual workstations can also be easily integrated into the conveyor line.

The system ensures a smooth material flow and can be flexibly adapted to the respective requirements thanks to its modular design. It is ideal for use in production lines, assembly technology and factory automation where particularly heavy workpieces are involved.

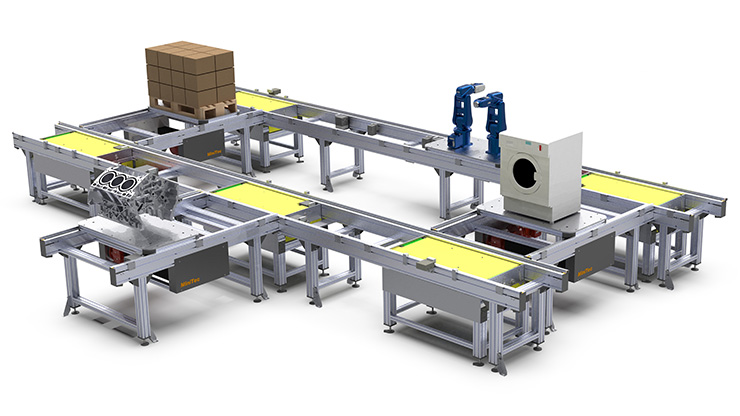

FMS Max is a further development of the tried-and-tested FMS transport system and can transport workpieces three times as heavy as the latter, namely loads of up to 700 kg per linear meter.

It has been specially developed for serial assembly and production processes and is suitable for both manual and automated production processes. Thanks to its modular design, the system can be flexibly integrated into different line configurations.

Its high load capacity makes it the ideal solution for transporting heavy and large-volume components in demanding industrial environments.

Another trade fair innovation in the field of conveyor technology is an exemplary stainless steel conveyor belt. The background to this is that MiniTec has expanded its existing portfolio based on aluminum profiles to include conveyor systems made of steel and stainless steel. In addition to the increased resilience and resistance of the materials, the smooth surfaces also play an important role. These meet the high requirements of producers in the food, pharmaceutical and chemical industries, which could not previously be met with the aluminum profile system.

MiniTec SmartAssist opens up completely new possibilities for interactive employee support for companies. The assistance system from MiniTec ensures faster learning of processes and individualised support during work, both in assembly and in packaging in warehouses and dispatch.

A connection between the worker assistance system and business management software, so-called ERP systems, will be presented as an innovation at Automatica. The interface allows the exchange of data, for example with materials management, production or warehouse management.

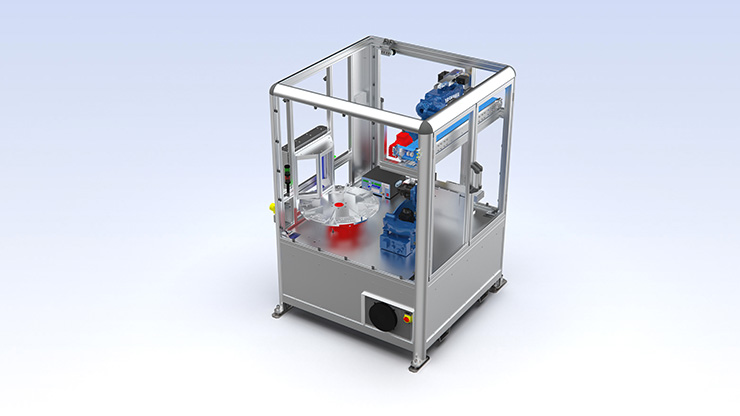

MiniTec has developed an innovative concept for individual systems based on standardized manufacturing cells. These are self-contained boxes that always have the same dimensions and an identical basic structure, but are equipped with different functions and technologies for the respective tasks.

MiniTec will be presenting an exemplary system based on this approach at the trade fair.

Venue: Trade Fair Centre Munich

Am Messeturm, 81829 Munich