- Products

- Solutions

- Service

- Company

At a company in the food industry, a plant in the packaging area was automated more strongly with MiniTec. A field report.

The customer's high quality standards, with a renowned international clientele, not only apply to the products themselves, but also to the entire manufacturing process. Against this background, they wanted to optimise a certain process in the packaging area and took MiniTec on board as a project partner.

The customer's high quality standards, with a renowned international clientele, not only apply to the products themselves, but also to the entire manufacturing process. Against this background, they wanted to optimise a certain process in the packaging area and took MiniTec on board as a project partner.

Are you planning a new assembly line or would you like to optimise existing production processes?

On a packaging line, the products are checked by a checkweigher at the end of the conveyor belt. They then fall into an outer carton. The carton change and the counter reset had to be done manually by the line staff. This process was not reliable due to the necessary intervention of the staff, which is why an additional checkweighing had to take place. Therefore, MiniTec was commissioned with the conception and realisation of a carton collector, which should automate this process and ensure a correct counting.

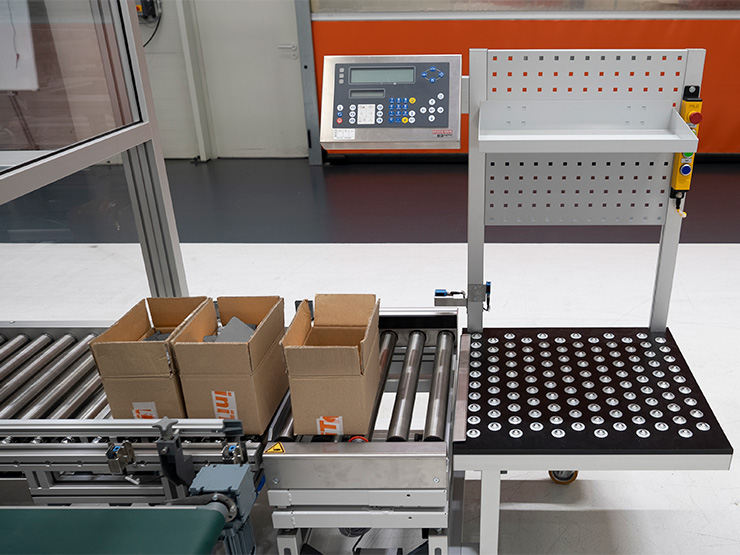

In the new system, the empty outer cartons are first made available on the supply line on the left-hand side. From here, they are automatically transported to the filling position. There, the finished product is held back in a hopper during the carton change. The hopper then opens so that the products fall into the carton. To ensure uniform filling, the carton can be advanced step by step after a predefined number of pieces. When it is full, it is transported to the removal position on the right side of the line, where there is a work platform for turning and closing the cartons by employees.

Ergonomics have also been taken into account - the outer cartons are mounted on a ball belt for comfortable working, so that the staff can turn the carton at their own discretion. There is also a small storage area for work and packaging materials.

When designing the system, MiniTec paid attention to the required flexibility because the packaged products have different sizes, colours and textures and also different sized cardboard boxes are used. In terms of throughput, a line output of up to 80 bags per minute had to be ensured. Depending on the size of the outer cartons, the timing and the step transport had to be stored automatically via the programme parameters.

MiniTec also took care of a high level of process reliability: the transfer of the bag formats had to be trouble-free and without losses. To ensure that, for example, the replenishment with empty cartons on the supply line takes place without interruption, MiniTec integrated a fill level monitoring system that guarantees a timely refilling of cartons via signalling or switches off the machine before cartons are missing at the filling station. This can be stopped via an interface to the upstream system. At the same time, a sensor system signals that a carton is correctly positioned in the station for filling. If cartons are missing or incorrectly waiting, an acoustic and visual signal is given and the system is switched off.

To ensure that the cartons always contain exactly the desired quantity of products, after they have been counted as they fall into the hopper, an additional counter-check is carried out at a weight monitoring station. If the weight is incorrect, a visual message is also displayed here and the further transport of the carton to the packing station is stopped.

The entire system is controlled via a central unit. The operation is designed according to ergonomic aspects - this also applies to the set-up processes.

After the carton packer has been in operation for a few months, the conveyor belt serves as a supply line for the empty outer cartons ... clear advantages of the new system have already become apparent. Incorrectly filled cartons are almost completely a thing of the past, and if they do occur again, they are immediately detected automatically.

According to the customer, the processes are now much more reliable and error-free, and at the same time the automation ensures faster, uninterrupted filling and thus higher productivity - mission accomplished with MiniTec.

Do you have any further questions about the semi-automatic packing machine?