- Products

- Solutions

- Service

- Company

How can the cleaning of workpieces with constantly changing diameters and shapes, in some cases also conical shapes, be automated - and preferably without time-consuming retooling? A dust removal system does this with the help of brushes and nitrogen.

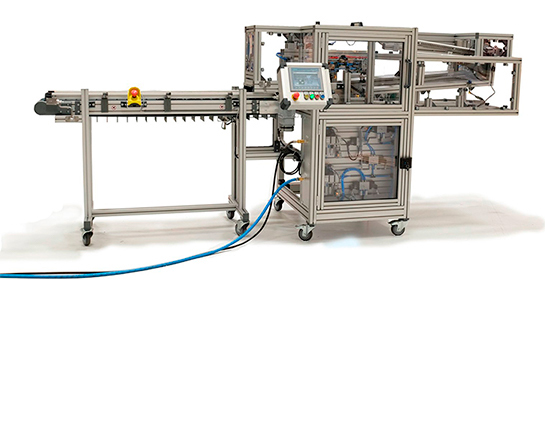

Cleaning contaminated workpieces by hand - this process is not only time-consuming, but also physically stressful for the exporter when large numbers of pieces are involved. MiniTec has therefore developed and built a dedusting system for a customer which can clean a wide variety of workpieces by means of brushes and nitrogen - with virtually no complicated and time-consuming changeover processes. The highlight here is that the supply and discharge is also integrated. "We had to try out a lot and were constantly faced with new challenges during the development process," say the two project supervisors Carolin von Ehr and Stefan Schütz. Today, a wide variety of molds can be fed, cleaned and also discharged on a single system. Currently, five different workpieces are running and that with only two changeover units.

The dirty workpieces are fed via a clocked rotary turret and an inclined plane, which enables the rolling of conical components without requiring a changeover of the feeder. A vacuum suction cup serves as a gripper, which is equipped with a spring-loaded thrust piece that adapts to any component diameter - thus no retooling of the gripper is necessary.

Rotating brushes and nitrogen

The cleaning process itself is carried out by means of a rotating brush and the supply of nitrogen under pressure, with which the workpieces are blown off - compressed air would be too impure at this point. A sensor checks the extraction system - the system only runs if it is functioning properly and the nitrogen can be extracted together with the contamination. On the one hand, this protects the system from contamination, but above all it protects the employees from nitrogen.

To change over to a new batch, all that is required is to replace the guide brushes on the front of the cleaning station with little effort. The side brushes hold the workpiece in position so that the vacuum gripper can grab it and discharge it on a cycle belt with welded-on bars. The webs prevent contact between the workpieces and thus damage. The flexibility of the system is almost limitless. It can also be equipped with rollers so that it can be positioned as desired, or it can be separated from the infeed and outfeed belts, thus making the operation more or less automated.