Quantity specifications from the order …

- Products

- Solutions

- Service

- Company

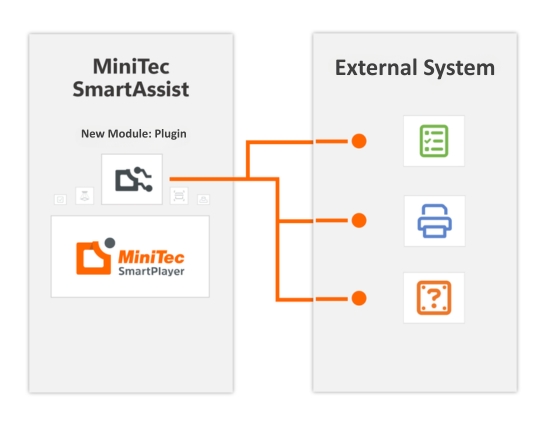

The plugin module not only enables integration with traditional ERP or MES systems, but also with other software solutions and hardware components.

Flexibility over one-size-fits-all

The challenge: The market offers a wide variety of ERP and MES systems—each with its own specific requirements for data exchange. A universal interface compatible with all solutions seemed nearly impossible. That’s why MiniTec opted for a more flexible approach and developed the new plugin module—an open development platform that can be individually tailored to each customer’s software environment.

“With the plugin module, we have every opportunity to adapt to our customers’ individual systems and requirements—with manageable effort,” explains Markus Kaiser, responsible for the development of MiniTec SmartAssist. “This level of flexibility is just as important to us as it is to the users of our assistance system.”

From order to assembly – in real time

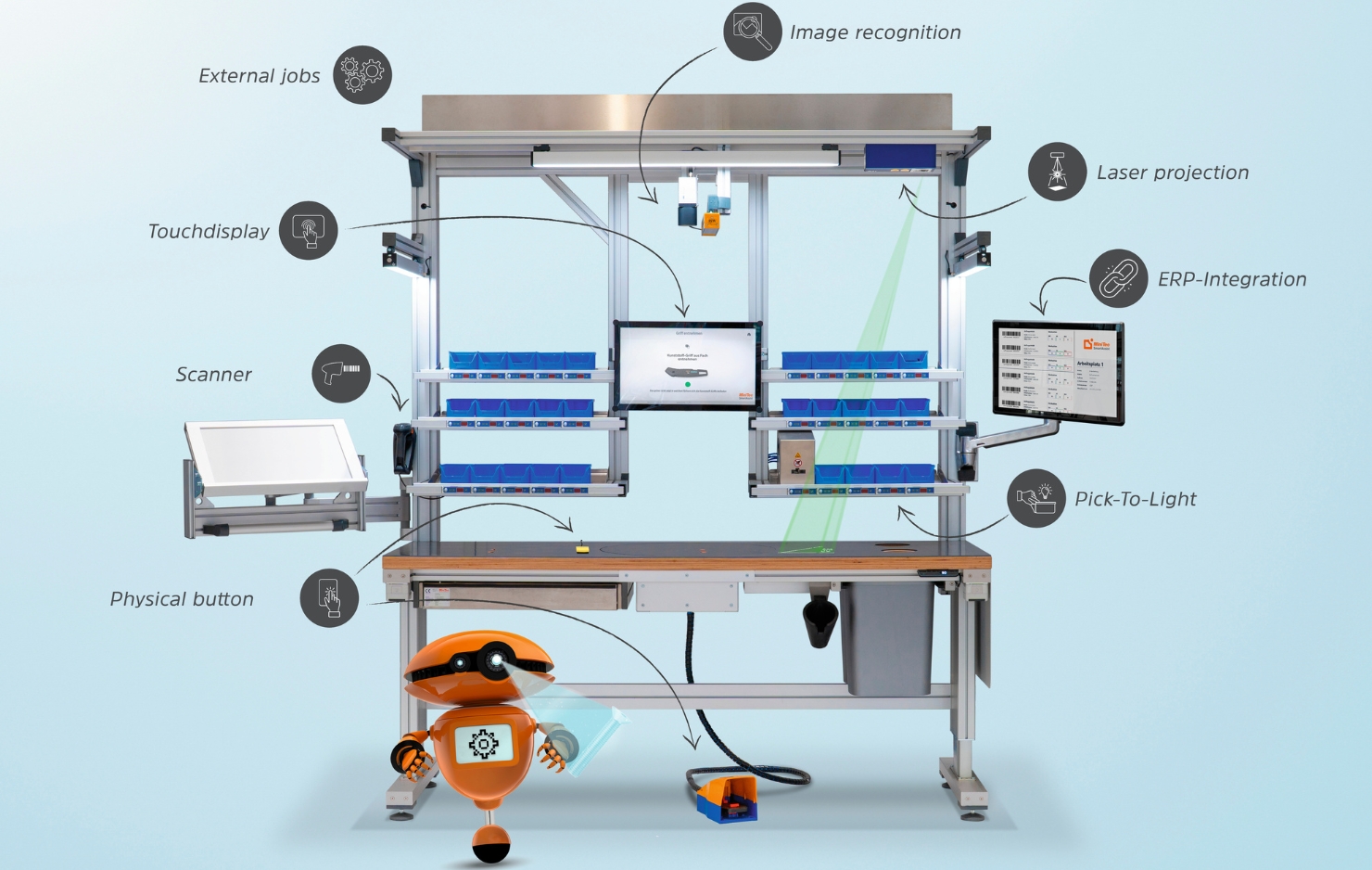

MiniTec demonstrated this in practice at the automatica trade fair through several real-world examples. For instance, order-specific information—such as the required wavelength for a linear unit—is directly transferred into the respective assembly step and displayed to the worker on the screen. This represents a significant efficiency gain, especially for manufacturers with numerous configuration options.

Another scenario involved automatic quantity tracking: the quantity defined in the order is transmitted to MiniTec SmartAssist, which counts every completed product and automatically closes the process once the order is finished. The system also distinguishes between good and defective parts. The results are then fed back into the ERP system. Additionally, MiniTec showed how labels are automatically printed in parallel with each finished product—an example of easy integration of additional peripheral devices.

Future-proof through openness

The open architecture of the module allows integration not only with traditional ERP or MES systems but also with other software solutions. It also supports the integration of hardware such as screwdrivers, scales, I/O modules (light barriers, signal lights, sensors, etc.), or customer-specific components. Even process workflows between different workstations can be controlled and coordinated via this platform.

This makes MiniTec SmartAssist an even more versatile building block for digital production processes—fully in line with Industry 4.0.

Get an overview of all modules for interactive workplace support.

New module enables integration of ERP and MES systems with MiniTec’s worker assistance system. MiniTec unveiled this innovation for the first time at automatica.

MiniTec SmartAssist is well on its way to becoming the standard solution for interactive support in manual workflows—such as assembly or order picking. Demand for integration with existing enterprise software has steadily increased in recent years. And for good reason: linking order management with worker assistance simplifies information flow, shortens lead times, and significantly boosts process efficiency.