- Products

- Solutions

- Service

- Company

The German footwear industry is part of global value chains. To enhance international collaboration and optimize manufacturing processes, the MELLOW research project was launched – with MiniTec among its five innovative partners.

The footwear industry in Germany is facing major challenges due to the increasing relocation of production. To remain competitive, many manufacturers rely on close collaboration with partners across Europe. This cooperation is essential for establishing common standards for quality, sustainability, and fair working conditions.

Digital solutions are particularly in demand when it comes to optimizing production processes within the value chain. Against this backdrop, the MELLOW research project (“Smart Collaborative Workflow Development in the Footwear Industry”) was launched. Together with application partners, AI-powered assistance systems are being developed and tested. At the same time, so-called collaboration islands are being used to generate new ideas for more effective cooperation within value creation networks.

The goal is to achieve improved working conditions, process efficiency, and product quality in international manufacturing networks. The foundation for this is the development of a digital assistant that uses sensors and AI to record workflows at different sites. This data is transformed into a process model, which is then jointly refined within the collaboration islands. The AI-powered MELLOW assistant, featuring technologies such as activity recognition and process mining, is designed to help detect errors at an early stage, improve product quality, and support workers in their manual tasks.

To produce economically in the German footwear industry, innovative concepts for collaboration with partners are required.

[Source: Wildling Shoes GmbH]

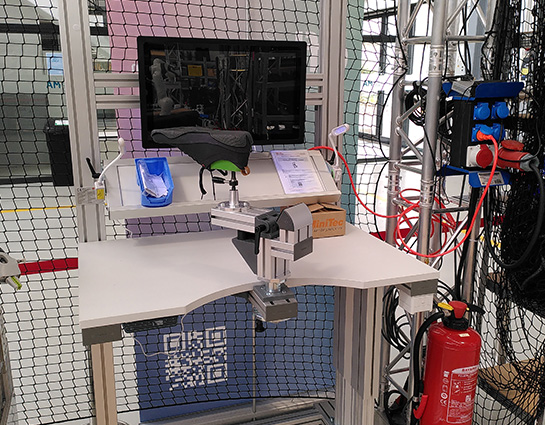

An initial development demonstrator – a base model for creating the workstations for use by manufacturing partners on site – is now in place in the DFKI Saarbrücken laboratory and has been tested against an initial use case from Wildling Shoes. A second use case from SOLOR will follow shortly.

Three Years to Achieve the Goal

The research project is scheduled to run for three years. The main objectives are:

The aim is for employees of the application partners to benefit from improved work processes in terms of occupational safety and productivity, as well as from cross-location knowledge exchange. To facilitate industry transfer, the results will be documented in the form of guidelines, workbooks, and other formats and made publicly available.

The creative minds behind the MELLOW project.

Important for the further development of MiniTec SmartAssist

MiniTec itself also benefits greatly from its involvement, says Andreas Böhnlein, Managing Director of Technology: “Through our participation in MELLOW, we gain valuable insights for the further development of MiniTec SmartAssist. This allows us to test new approaches in practice – such as process mining as a basis for digitalization and collaborative optimization of existing workflows. The know-how gained will be incorporated into the ongoing development of our system. The sensors used in MELLOW also provide a testing platform on which hardware and software modules for MiniTec workstations can be developed, enabling us to offer customers a comprehensive package that covers everything from data acquisition to import into MiniTec SmartEdi. In the end, our customers will benefit most from the project – naturally not only those from the footwear industry, but from all sectors.”

The “Smart Collaborative Workflow Development in the Footwear Industry – MELLOW” project (funding codes 02L23B040 to 02L23B044) is funded as part of the “Future of Work” program by the Federal Ministry of Education and Research (BMBF) and the European Union through the European Social Fund Plus (ESF Plus) and managed by the Project Management Agency Karlsruhe (PTKA). The responsibility for the content of this publication lies with the author(s).

Workstations and Assistance System by MiniTec

A total of five partners are involved in the MELLOW project, including MiniTec. The other participants are ITA Kaiserslautern (Institute for Technology and Work), which also coordinates the project, DFKI Saarbrücken (German Research Center for Artificial Intelligence), and two companies from the footwear industry – Wildling Shoes from Engelskirchen and SOLOR from Pirmasens.

Within MELLOW, MiniTec is responsible for two major areas. The first is the design and production of the workstations, which are instrumented in collaboration with the German Research Center for Artificial Intelligence and installed and operated at the application partners’ sites. Sensors are supplied by the German Research Center for Artificial Intelligence.

The second, more extensive task is to extend MiniTec’s SmartAssist assistance software with a data interface, enabling the aggregation of sensor data. After evaluation using process mining technologies, this data is imported into the enhanced MiniTec SmartEdi editor. This allows the collaboration islands to optimize the recorded processes and then visualize them on the workstation’s assistance system.