- Products

- Solutions

- Service

- Company

As demand for a popular office chair reached unprecedented levels, Interstuhl Group had to increase its productivity. This was only possible with a new assembly line. The solution came in the form of a heavily modified UMS system from MiniTec.

Tieringen, located in the heart of the Swabian Alb, is a recognized recreational area with just over 1,000 inhabitants and is a district of Meßstetten. In this beautiful setting is the headquarters of the Interstuhl Group. Over the past 60+ years, the family-run company has grown with passion and innovation into an internationally successful provider of tailored product and space solutions, as well as services. Around 800 people work at Tieringen, with another 350 employed worldwide at production sites and sales offices.

With its three strong brands—Interstuhl, Bimos, and Backforce—the Interstuhl Group’s products are used not only in office environments but also in production areas, laboratories, and gaming setups. While some customers are individual clients, the majority of sales are made globally to major clients across all sectors of industry and administration. The range of chairs and furniture is characterized by a high degree of variety. For seating, for example, there are different fabric qualities, bases and casters, as well as backrests with mesh or upholstery in high or low versions. Many of these features can be combined, bringing together ergonomics and the individual needs of the customer.

Pallet Circulation System UMS as the Solution

In their search for a suitable supplier, the Interstuhl Group quickly came across MiniTec, recalls Sascha Seemann, also working in equipment design at Interstuhl:

"There are very few suppliers who can offer such a pallet transport system at an economically attractive level."

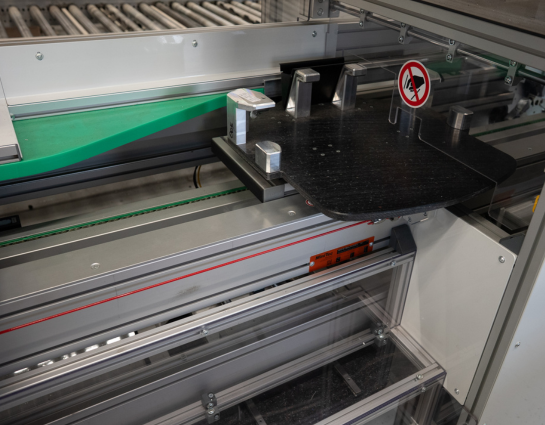

MiniTec impressed the Interstuhl Group with its pallet circulation system UMS. This highly space-saving solution enables empty pallets to be returned beneath the conveyor level. Pallet accumulation is possible not only on the conveyor itself but also during the return transport of unloaded workpiece carriers. A key feature of the UMS series is a continuously circulating chain that moves the carriers in a closed loop.

However, it soon became clear during project discussions that the UMS base concept could not be applied to Interstuhl’s requirements on a one-to-one basis. During assembly, the backrests of the chairs extend downward, where they could potentially collide with the returning pallets underneath the system. Furthermore, the workpiece carriers are equipped with a relatively large base plate to ensure the chair, including its seat, fits entirely on the carrier during assembly. The armrests also require additional space in this configuration.

The project team was therefore faced with the challenge of meeting the specific requirements of the workpieces while taking into account the limited space available. Retaining the standard UMS concept would have required the system’s cross-section to be significantly larger—a solution ruled out by the spatial constraints. The answer was found in a comprehensive adaptation of the UMS system to Interstuhl’s needs—achieved through a combination of different measures.

More Powerful Final Assembly Required

The Interstuhl Group boasts a remarkable level of vertical integration, with many steps in the furniture manufacturing process carried out in-house. The company operates its own steel construction facilities, where various base components are welded and stamped. Coating is also handled on-site. In addition, there is an in-house fabric warehouse, where materials are cut before moving on to the sewing department and later to upholstery. In the foaming department, backrests and seat foams are produced, which are then assembled into upholstery units and back components during pre-assembly.

Naturally, final assembly and shipping preparation also take place at the company’s headquarters in Tieringen. Here, components are either packaged in partially disassembled form or fully assembled before being shipped out via Interstuhl’s own logistics services.

For years, one of the assembly lines has been dedicated to producing the EVERY office chair. Its growing popularity turned it into a true high-runner. However, steadily increasing demand eventually pushed the line to its limits. As equipment design engineer David Rieble explains: "This line was never designed for such high volumes. It relied on gravity: workpiece carriers were carts that rolled independently from left to right along inclined rails, linking the different assembly stations. In addition, the chair underwent a facelift, but the line had originally been designed for the previous model."

Against this backdrop, the Interstuhl Group decided to replace the system with a new, significantly more powerful assembly line. Unlike its predecessor, the new system would no longer operate by gravity but instead use its own drive mechanism. Another requirement was that, due to the limited floor space, the system needed to be highly space-efficient, with workpiece carriers running in a closed loop.

Extensive Adaptations Required

While a UMS system is normally supported by legs mounted at regular intervals on a profile frame, the Interstuhl installation was designed with a solid C-beam frame forming the supporting structure at both ends of the system. This meant that the pallet guides in the lower section no longer needed to serve a load-bearing function—an approach that saved a considerable amount of space.

When the workpiece carriers return to the upper level after circulating, they are guided forward so that the chair, complete with armrests, can be transported without risk of collision. This design also offers the additional advantage that workers do not need to lean as far forward. Once assembly is complete, the table retracts and can be lowered through the system. As David Rieble explains: "This also allowed us to save some overall system width."

Ergonomic Handling and Tailored Design

Another major requirement was that, after final assembly, the chair should no longer need to be lifted before being turned over—instead, it should simply be pulled off the workpiece carrier. As David Rieble explains: "This was not possible before, because if armrests were involved, collisions with the system or the conveyor would occur. We therefore designed the workpiece carrier with the mounting plate and brackets ourselves, making this process possible. In addition, the brackets are designed to be adaptable for other chair models as well."

These and other adaptations resulted in a coherent, customized system concept that perfectly meets Interstuhl’s requirements.

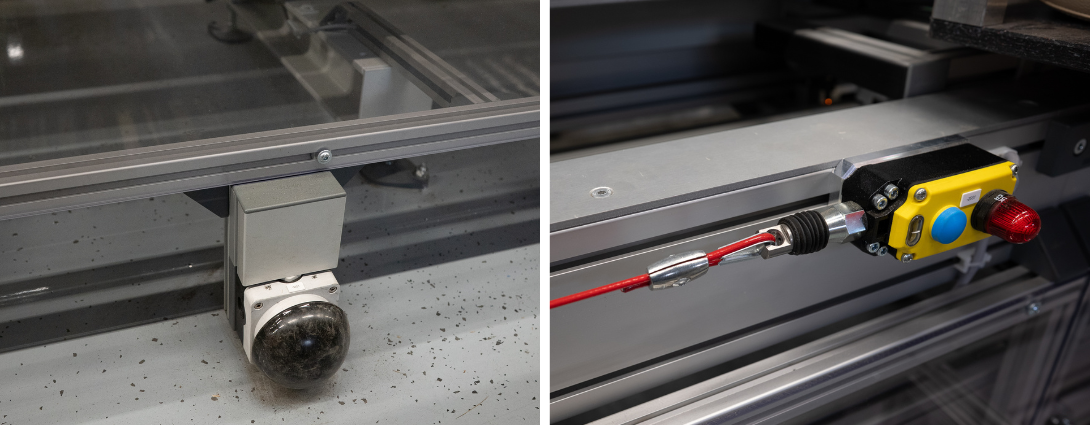

Thoughtful Control System for Safety and Comfort

The system is designed with five assembly stations, though currently only three are in use by two operators. The process begins with the insertion of the seat. Next, the armrest carriers, the mechanism, and optionally the armrests are installed, followed by the assembly of the backrest carrier. Finally, the chair column and base are mounted.

Once an operator completes a step, they advance the workpiece carrier using a foot pedal. After assembly is finished, the chair is removed, and the empty carrier is returned and lowered via foot pedal. In the future, control via a display is also planned. These displays will show operators their work orders and indicate which chairs need to be assembled.

Improved Productivity and Flexibility

Already after the first few months of operation, the benefits of the new system are noticeable. As David Rieble explains: "The feedback from our department managers has been consistently positive. They are very satisfied with the workflow. In terms of speed and productivity, we are definitely ahead of the old system. The operators are also pleased and praise the simplifications brought by automation. Regarding flexibility, we have improved as well. With five workstations available, we can, for example, handle additional tasks that arise at short notice. It is also, as mentioned, easy to modify the design of the workpiece carriers, allowing us to produce additional chair models on the system."

The collaboration with MiniTec was also very positive, according to Sascha Seemann: "This was our first project with MiniTec, and we can report nothing but positives. We always coordinated promptly via online meetings or by phone, allowing the system to be implemented fairly quickly. This also included fine-tuning specific details, such as the in- and outgoing system described earlier. Ideas were always exchanged from both sides, and the collaboration was smooth."

Accordingly, the Interstuhl Group is open to further projects in the future, such as another system of a similar type. They are also interested in MiniTec SmartAssist and can easily envision using the operator assistance system for pre-assembly of the backrest or seat modules.