- Products

- Solutions

- Service

- Company

How do you manage a large order - this is exactly how the situation at Bizerba in Meßkirch can be summed up in the summer of 2021. In itself a positive event, the task was to increase production capacity six-fold in the shortest possible time. In order to achieve this, MiniTec was brought on board.

Bizerba SE & Co. KG, headquartered in Balingen, is a classic German medium-sized company. Family-run with over 100 years of history and high quality standards, but at the same time innovative and also internationally oriented. Bizerba is particularly known for its store scales, which is also the origin of the company. However, Bizerba has further developed into a solution provider for the food industry - this includes packaging machines, labelers and, in particular, cutting machines.

The latter are manufactured at the Meßkirch site. This involves devices in various sizes for sausage slicing - from countertop devices for bistros and chain butcher shops to industrial slicers. Bizerba's innovative strength is demonstrated, for example, by the SmarterSlicing technology for networking and operator support of slicing machines. The vertical range of manufacture is enormous and extends from the aluminum blank through mechanical processing to final assembly.

Bizerba in Meßkrich - from here precision cutting devices go all over the world.

Word of the quality from Meßkirch has long since spread to the American market. This led to a customer from the USA placing a major order with Bizerba in the summer of 2021 for the delivery of a five-digit quantity of slicing machines, to be delivered by the summer of 2023. This specifically involved devices of the type GSP ("Gravity Slicer Premium") - so-called inclined slicing machines, which are particularly popular in the USA. Due to the inclined arrangement of the carriage, the material to be sliced does not have to be pressed on by hand, but is already firmly in place due to gravity. This makes work easier for the operator, especially with heavy material, and also ensures that the slices are always of the same thickness. The order from overseas was of course also an organizational challenge - after all, it involved a six-fold increase in the normal production volume in the GSP area and a doubling of the total turnover at the Meßkirch site. Production planner Jochen Lude explains: "We had to increase production capacity drastically, and as quickly as possible. That means hiring new employees, but also expanding the assembly stations. Although we have our own production equipment, it was already being used elsewhere - for example for renovation work and the dismantling of existing production equipment. That's why we decided to purchase finished assembly workstations from MiniTec." The decisive factor was, on the one hand, the aluminum profile system, which convinced as a stable and at the same time versatile construction basis. On the other hand, Bizerba had already been working successfully with MiniTec for many years at its headquarters in Balingen.

In general, it was also necessary to speed up final assembly in the course of the expansion. Previously, one employee had completely assembled a cutting machine. In addition to the enormous space requirements, this also had other disadvantages. For example, collisions often occurred because each employee worked at a different pace and the common tool was never ideally positioned. In the future, assembly was to be carried out by 4 employees over 4 cycles, at assembly islands. As part of the changeover, the walking and gripping paths for the employees were to be optimized.

The project started in October 2021, and it quickly became clear that the new assembly islands would initially have to be implemented without automation in order to stay reasonably on schedule. Everything then went very quickly, according to Lude: "We ordered in December and were already able to set up the first two lines at the end of February, albeit still without automation - that was immense! Together with MiniTec, we then successively set up further lines in a 6-week rhythm and added automation to the already existing assembly islands. Thus, by July, we already had the complete assembly line running, including automation." This approach enabled Bizerba to ramp up assembly capacity with new manpower at a very early stage, albeit still without automation.

Jochen Lude praises MiniTec's flexibility and willingness to cooperate: "Of course, it was rather untypical that we first purchased partially completed assembly systems, and we were glad that MiniTec went along with us. At the same time, a floor renovation took place during the course of the project and we continued to produce completely. This means that MiniTec's assemblers had to set up the new line within this area during normal production. These were difficult conditions, and I would like to commend the MiniTec installation team on this!"

In order to make the sporty schedule possible, the project team from Bizerba was able to exchange information directly with the MiniTec design engineers at any time. Lude comments: "The response times were always very short. If we had a question in the morning, there was usually an answer and a proposed solution by lunchtime, at most the next morning."

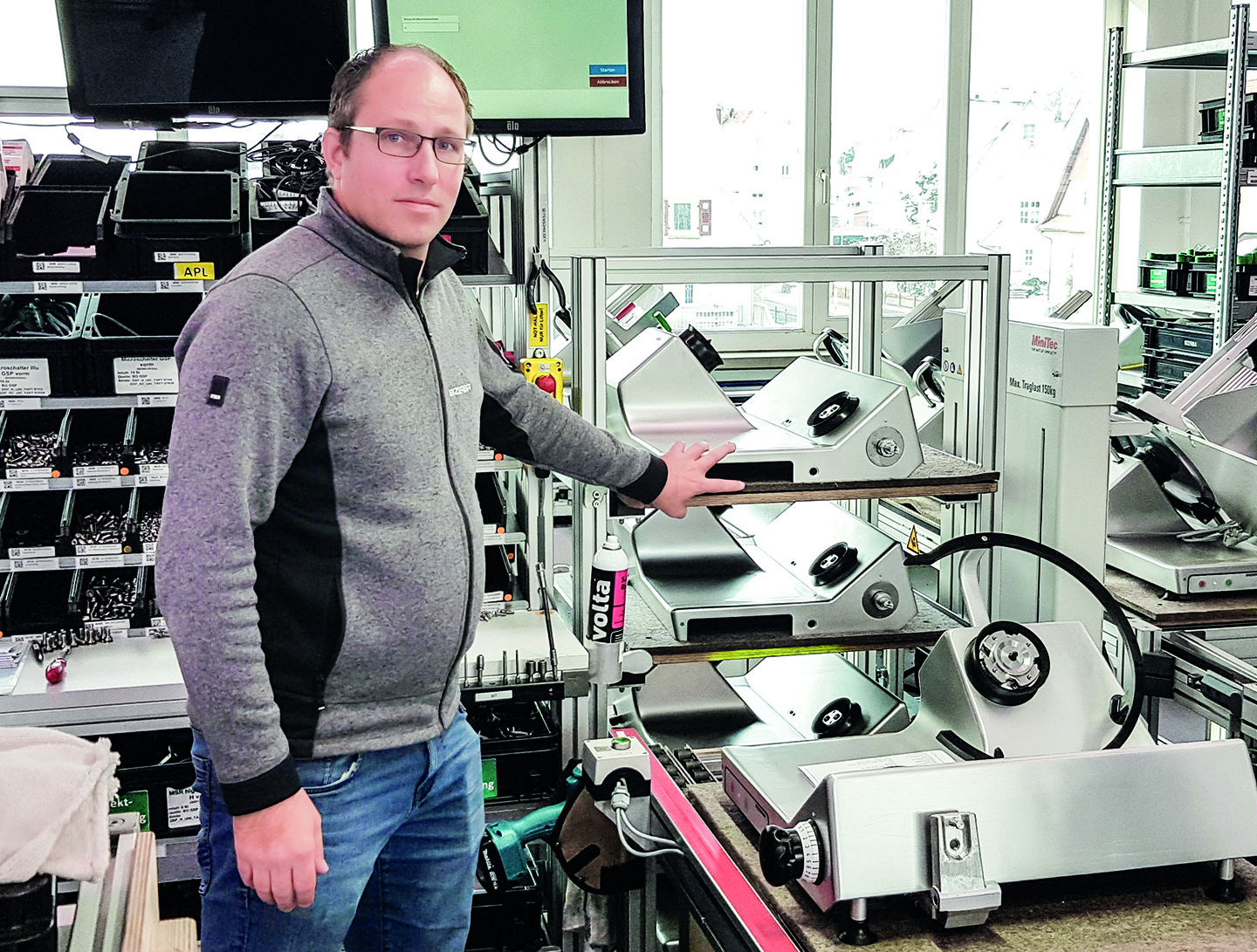

GSP HD cutting machines from Bizerba with inclined arrangement of the slide.

The assembly islands provide for more teamwork and productivity (3D model of the construction).

In the GSP HD final assembly line, 350 components are to be assembled in four substeps. Due to the limited space available, the assembly islands had to be designed as a U-line - instead of an I-line, where all four workstations would have been in one row. The U-arrangement also has the advantage that it gives the employees a little more "space" and they can also exchange ideas while working because they are facing each other.

At the beginning, the aluminum housings from pre-assembly are brought to the first work station by transport trolley. The trolley is pushed onto a fork and lifted to the desired removal height by means of a lift. From here, the employee pushes the housing via a roller bar to his assembly station and pneumatically lifts it, including the workpiece carrier, to his desired working height - Bizerba placed great emphasis on ergonomics. After he has completed his assembly work, he lowers the housing again and pushes it on to cycle 2, where the next employee continues with the assembly. In order to then move the unit to the other side to employee 3, MiniTec has implemented an automatic transfer unit. The employee in cycle 2 pushes the device to the right. In doing so, he triggers a sensor, which places the device on a conveyor line. The employee in cycle 3 can now request it by pressing a button. Once assembly has been completed, he lowers it again and transfers it to cycle 4. Once assembly has also been completed there, the fully assembled cutting machine is transferred to an older roller conveyor, which travels along the wall to a central machine elevator. Here, MiniTec had another special feature to consider, because the control system of the old belt was not to be interfered with. Therefore, an automated outfeed conveyor was developed. When employee 4 is finished, he pushes the unit to the right, a sensor responds and toothed belt conveyors start to discharge. At the same time, the main conveyor belt is blocked by stoppers so that the machine can be discharged onto it. On the skin conveyor, the machine is then fed to the final inspector or the upstream laser to create the rating plate. It then goes down one floor to shipping via the machine elevator.

A micrologistics specialist ensures that the required material is always available at the assembly islands in the GSP production area - i.e. both the pre-assembled machine housings and screws and other components. The latter are brought to him by employees from the central warehouse to an intermediate area, from where he collects them by means of transport carts and distributes them further. Bizerba relies on kanban control for material supply. In the case of the pre-assembled machine housings, this is done on sight - as soon as the micro-logistics specialist notices that the cart at an assembly island is becoming empty, he replaces it with a full one.

All other components go through container Kanban. The material number is married to the bin, a barcode and a storage location. When the first box becomes empty, the worker packs it into a MiniTec return. The second box slides in, and the worker works out of the second box. The micrologist takes the first box and brings it to the central transfer station. The empty crate then goes from there to the main warehouse, is refilled and provided to the micrologistics operator again at the transfer station. The transport carts, including the special carts for the machine housings, also come from MiniTec.

The flow of materials is controlled by Kanban.

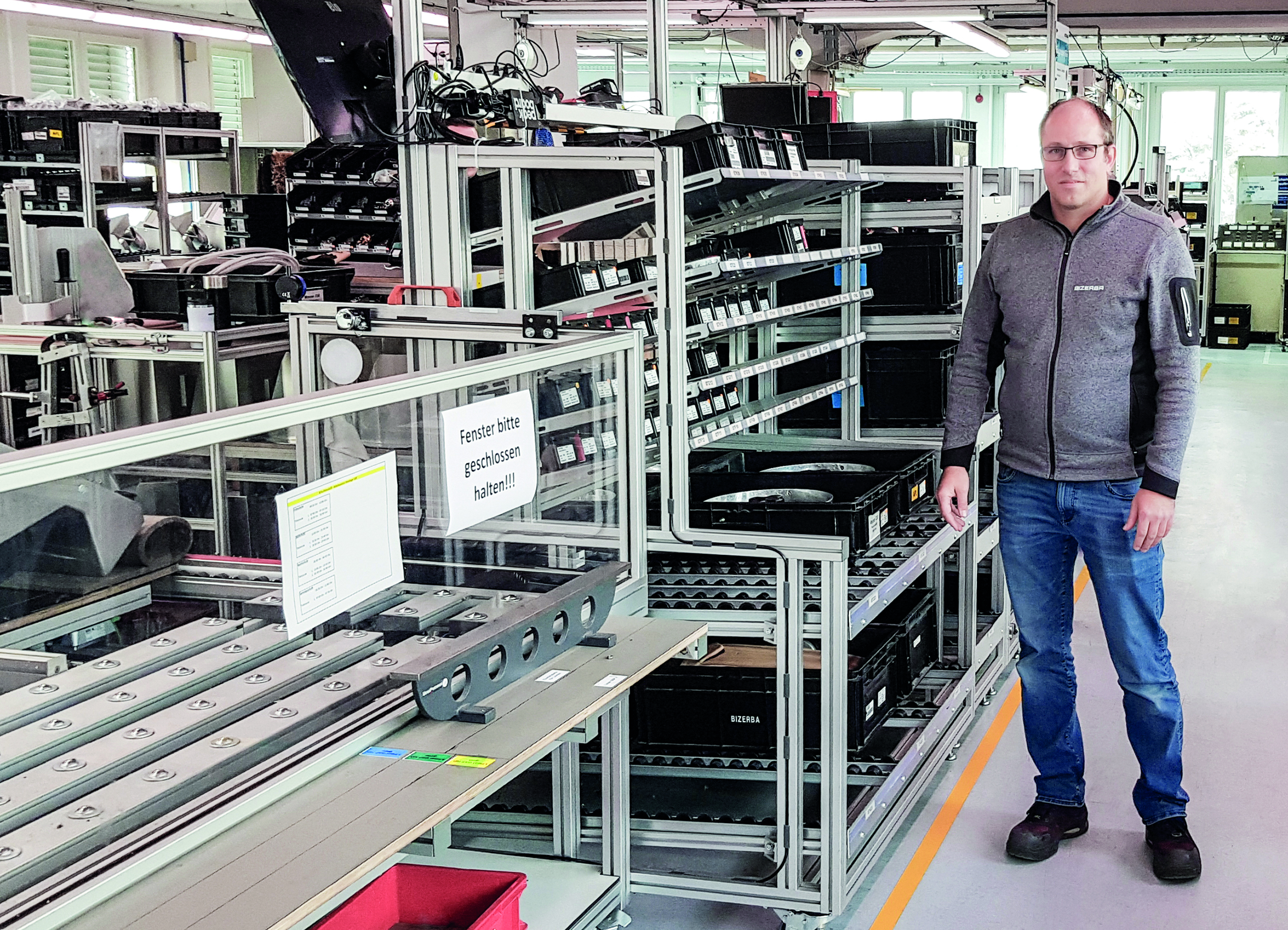

Production planner Jochen Lude was able to significantly increase production thanks to the assembly islands.

The expansion of production and the associated change in the working principle to assembly islands was a complete success for Bizerba, according to Jochen Lude: "Thanks to the rapid and flexible implementation of the assembly islands with MiniTec, we can adequately serve the order from the USA. In addition, we were able to significantly accelerate the output of devices per shift by switching to work-sharing assembly.

There are hardly any downtimes or congestion phases. Of course, this is also due to the improved ergonomics. The tool is now always in the same position. The employee gets a certain routine. By dividing up the overall work content, it is also easier to train new personnel because the scope of work for the individual is no longer so large - he only has to know a section of the cutting machine. This is a big advantage for us in the current situation, where we need 25 percent more personnel."

Based on the positive experience with MiniTec, the production planner is already thinking about further joint projects. These will primarily involve digitalization in assembly, with topics such as the MiniTec SmartAssist worker assistance system and the integration of RFID tags.

You need a corresponding solution or a solution approach for your project? Then please feel free to contact us!